Experience & Facilities

years experience

sets equipments

㎡ production base

Complete Track Undercarriage

Sprocket (Drive Wheel)

Idler (Tension Wheel)

Top Roller (Carrier Roller)

Bottom Roller (Track Roller)

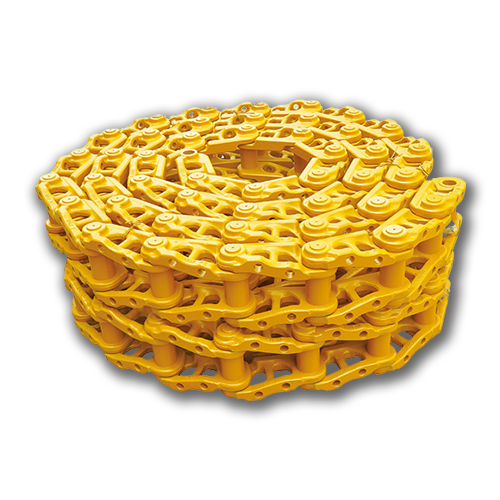

Track Chain (Track Link Assy)

Track Shoe (Track Plate)

Track Group (Track Assembly)

Track Adjuster (Tensioner)

Travel Motor (Final Drive)

Rubber Track

Bushes & Pins

Bolts & Nuts

SHENGDE MACHINERY

Track undercarriage expert

Since 1999, Shengde machinery has been committed to R&D and manufacture of complete track undercarriages for various crawlers. Company is the official supplier of many OEMs including Sany, Zoomlion.

- Products lineups:

- Complete track undercarriage, track chassis

- Steel track group, track chain and track shoe

- Sprocket(drive wheel), idler(tension wheel), rollers(top roller, bottom roller)

- Idler bracket, track link, track shoe, bushing, pin, bolt and nut

- Chassis frame, travel motor(final drive), swing motor, track adjuster

- Rubber track, rubber pad

Annual production volume: 20000 sets of track chassis

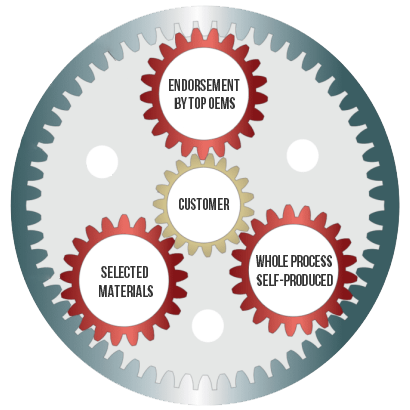

Why choose us?

Customer value is our core. We apply material inspection and performance test to ensure quality. Self-owned production line keeps us flexible for the specific demands. As the official supplier of many OEMs, we've been through hundreds of projects. Rich experience guarantee the product performance in your real field applications.

Material inspection and performance test

Materials are selected base on quality and performance analysis. We also routinely implement performance test for every batch of products before shipment.

Authorized supplier of OEMs

ShengDe Machinery has built long-term cooperation with many OEMs. We are now the authorized tracked undercarriage supplier of Sany Group and Zoomlion Heavy Industry.

Complete self-owned production line

From forging → machining → heat treatment → finishing → assembling → painting → packaging. Every step is under control, every step is adjustable for actual demand.

Company News

Performance Test

Quality Standards: ISO9001:2015, ISO14001:2015, OHSAS18001:2007, ERP System

Assembling

CNC floor boring, CNC gantry milling, CNC large-scale bending machine, CNC lathes, semi-automatic assembly line etc

04

/

26

News & Events

Shengde Machinery will be 2024 Xuzhou International Engineering Machinery Exhibition

Track undercarriage expert. Since 1999. Main business: design, produce and wholesale track undercarriages, steel tracks and all undercarriage parts.

CONTACT US

Service Mail: info@cnqzshengde.com

Service Line: +86-595-6829-6580

Sales Manager: +1-213-246-6396

Tel: +86-595-22450505 / 22451159 / 22425555

Postcode: 362000

Copyright © 1999 - 2026 Shengde Machinery All rights reserved - Unified Social Credit Code: 91350502705285683C

Powered by Shengde Machinery International Trade Department | SEO

Track Undercarriage Factory | Wholesale Track Undercarriage | Track Undercarriage Parts